Product

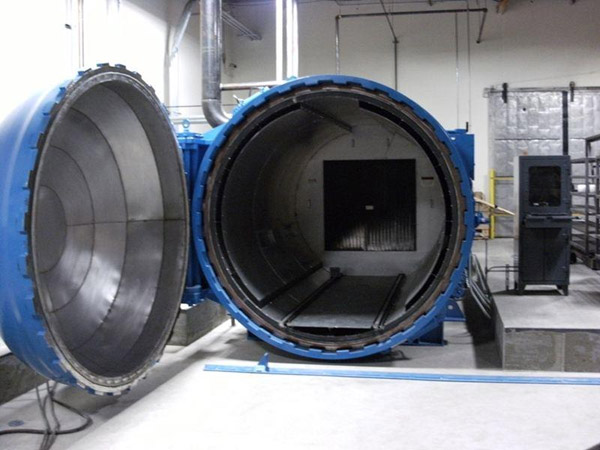

Glass Laminating Autoclaves

Our custom and standard lines of glass laminating autoclaves are used in the production of diverse automotive, architectural, safety, and decorative glass. From small car windshields to large laminated glass, we build autoclaves in lab sizes and large, high production models. Designed to suit your specific load and laminated glass processing requirements, Melco Steel, Inc. autoclaves are available with auxiliary support equipment such as cooling, pressurization, as well as vacuum systems.

To meet intensive production requirements, we provide autoclave systems packaged with heating power and air circulation units. The innovative design in these systems allows excellent heat transfer and accurate temperature uniformity. Safety features of our glass laminating autoclave systems include door safety interlocks, ‘Operator-Inside’ alarms, and blower motor cooling alarms. We manufacture glass laminating autoclaves in flat-sided workspace designs for maximizing load capacity. Our proprietary blower motor design is ideal for high temperature operations.

A cooling system is used to limit motor capsule temperature. Operators can easily access the motor by removing the water-cooling supply and return lines of the motor capsule. The main autoclave cooling is controlled by a proportional valve that provides excellent temperature control and does not induce thermal shock in the cooling coil. Advanced computer control systems in our autoclaves provide intelligent, optimized cycle processing for maximum production and highest quality.

We design computer controls specifically for glass laminating autoclaves to ensure high levels of accuracy and flexibility. Typical features of our control systems include guaranteed soak, glass temperature monitoring, automated vacuum leak checking, interactive screens, and multilevel security. Controls can also be configured to help reduce electrical demand charges. Melco Steel’s advanced vacuum controls adopted from aerospace applications enable OEMs to flexibly process standard and special interlayer materials.

Glass Laminating Autoclaves Specifications

Autoclave Specifications

Equipment Capabilities

Materials

Carbon Steel

Stainless Steel

Maximum Working Diameter

32 ft

Maximum Working Length

Maximum Operating Pressure

Maximum Operating Temperature

1500 °F

Maximum Wall Thickness

8 in

Pressurizing Medium

Air

CO2

GN2

Heating Methods

Electric

Heat Transfer Fluid

Steam

Autoclave Parts

Blower Motor

Circulating Fan

Cooling Coil Heat Exchanger

Quick Opening Door

Rupture Disc

Safety Relief Valve

Shielded Electrical Heating Unit

Standard Features

- Encapsulated blower motor eliminates the high maintenance necessary for through the vessel shaft sealing.

- Proprietary blower motor design allows operation at any combination of pressure and temperature.

- Engineered circulating fan assures excellent heat transfer to the load and exceptional temperature uniformity.

- Proprietary method of placing and securing insulation minimizes heat loss through the pressure vessel and minimizes operating costs.

- Location of typical electrical heating unit is shielded by cooling coil to prevent radiant heating of load.

- Cooling coil is a single pass heat exchanger designed for precise temperature control with ample provisions for thermal expansion to minimize thermally induced stresses and failure.

- “Man-Inside” emergency alarm cables are provided on larger autoclaves which allows operator to completely disable all autoclave sub-systems. It requires autoclave door to be opened to reset the alarm.

- Load track and floor is designed to allow for thermal expansion yet provide full structural support.

- ASME approved safety relief valve and rupture disc are provided on separate vessel penetrations to assure independent and safe operation. Many other redundant safeties are incorporated to assure operator and equipment protection.

- Most vessel penetrations, such as vacuum, thermocouple and cooling are built into removable and replaceable ANSI flanges. This allows easy modification or repairs without compromising the structural integrity of the vessel.

Harris Quick Opening Door Features

- This proprietary breech lock door allows full and easy access to the autoclave interior within one minute after completion of a curing cycle.

- Safety is inherent in its design, but we also include mechanical, hydraulic, electrical, and pneumatic interlocks to prevent door operation while the autoclave is pressurized.

- No relative motion of the door with respect to the pressure seal provides long o-ring life.

- An oxygen sensor/fresh air purge safety interlock is available to prevent opening the door unless safe levels of oxygen are present. This complies with recent OSHA rulings.

Capabilities

Services

Support Services

Instrumentation Options

Control Systems Features

- Intelligent plus Optimized Cycle Processing for maximum production and highest quality

- Guaranteed Soak

- Glass Temperature Monitoring

- Automated Vacuum Leak Checking

- Natural Pressure Decay of Temperatures and Pressure

- Interactive Screens

- Multilevel Security

Control Capabilities

Multiple Equipment Computer Control Monitoring

Recording with Backup

Control Options

Honeywell Computer Controls

Manual Controls

Network Compatible Computer-Based

Control Systems Programmable

Microprocessor-Based Controls Systems

Set Point Controls

Recording Options

Vacuum Control Types

Automatic

Manual

Vacuum Monitoring Options

Auxiliary Systems

Options Available

Vacuum Pumps

Lift Tables

Bridges

Load Carts

External Cooling System

Bridge Mechanism

Oxygen Sensor/Air Purge/Safety

Interlocks